MANILA – San Miguel Corp. (SMC) is building roads out of recycled plastics to help reduce the impact of plastic waste on the environment.

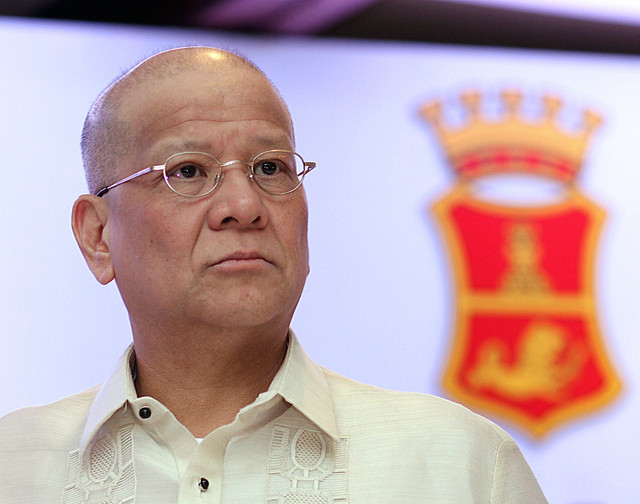

“This initiative is part of our push towards greater sustainability. Two years ago, we announced our major water sustainability project: to cut SMC water use by 50 percent by 2025. Recently, we reported that we beat our 2020 intermediate deadline of 20 percent reduction, by two years. Last year, we announced another initiative, and that is to address solid waste pollution. This project is part of that goal,” SMC president and COO Ramon S. Ang said in a news release issued Monday.

SMC will be working with leading materials science company, Dow Chemical, for the project that will use hard-to-recycle plastics as an alternative raw material input to asphalt for road building.

“Developing roads using plastics that would have otherwise ended up in landfills or our bodies of water is an environment-friendly method of disposing of scrap plastics,” he said.

“We can help our environment and at the same time improve the quality of our infrastructure projects. We are eager to begin this initiative,” he added.

Among the benefits of using recycled plastics for road surfacing are: improved stability and durability of roads; increased skid resistance, which improves road safety; longer lifespan of roads; lower asphalt costs, and less waste destined for landfills.

Dow has worked on projects that use plastics for modifying the properties of bitumen, used in making asphalt, which has been tested in India, Indonesia, and Thailand.

Initially, SMC will test out the technology in small municipal roads, as well as sidewalks and parking lots.

If the technology proves effective and meets all safety and quality requirements, the company may roll it out for larger infrastructure projects, Ang said.

“While we are proud to be the first-mover in this area, we are very hopeful that we won’t be the last or the only ones. The research is there and available to everyone, and we’ll be glad to share our own processes and experience. At the end of the day, this kind of innovation will benefit the same environment we all share,” Ang added./PN